SUMMARY: cFI, pFI & Optimization

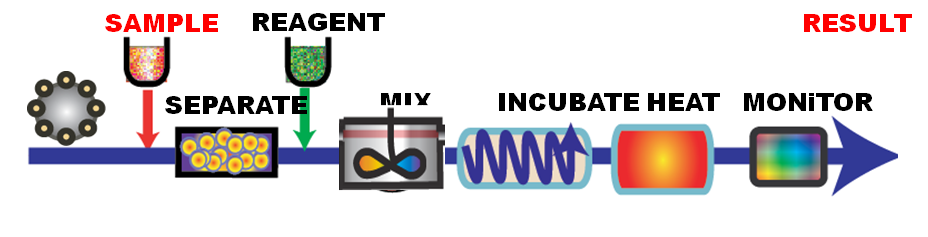

We have seen how flow programming and flow path optimization enhances performance of a variety of flow based assays, by optimizing kinetic requirements of the individual operations.

Without doubt, separations, on line sample pretreatment such as UV or heat assisted dissolution and decomposition, or UV assisted conversion ( such as nitrate to nitrite conversion by Lachat), will also benefit from flow path design and flow programming.Yet, at the outset of each such project it is important to ask, what is the goal of the intended assay. Is it a high throughput, or high sensitivity or reduction of reagent consumption. And if the goal is robustness and portability, then one should also consider micro Sequential Injection, for which an advanced flow programming (Chapter 2). Is being developed, inspired by the advances in pFI presented here.

What is remarkable, is the similarity of the flow design, used in all previous examples – the same pump configuration, the same flow rates in all channels-a feature quite different from present commercial systems (Lachat, OI Analytical, Seal) which all use peristaltic pumps furnished with a bewildering variety of pump tubes of different diameters. Thus each pump channel, generates, quite unnecessarily, a different flow rate, while all channels of the pump are merrily and continuously running all the time as long as the instrument is switched on.

Peristaltic pump is not an ideal tool, it is a “legacy technology”, inherited from AutoAnalyzer, used without much improvement or thought. It is time to move on and to think about alternatives.

1.2.38.